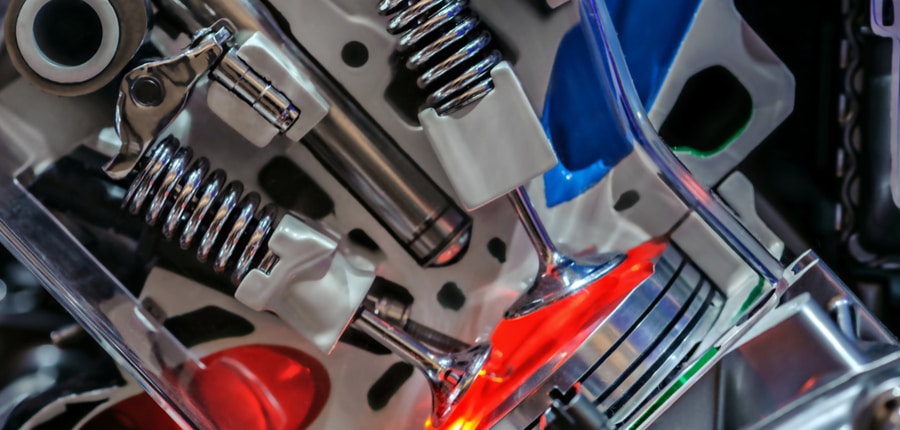

A fuel injector is essentially a solenoid with a fuel supply and a spray nozzle. It is connected to a fuel rail, and when the solenoid is energized a valve opens allowing fuel to pass through the nozzle end. The fuel injector is supplied with fuel pressure from the rail and the ECM (electronic control module) controls the electrical signal to the injector; opening it for a specific amount of time and injecting the proper amount of fuel into the cylinder.

There are three main kinds of gas-engine fuel injector:

TBI, or throttle body injector – This is the simplest and oldest set-up, where a single injector sits in the throttle body and supplies the fuel for the engine. It’s fairly easy to diagnose and replace.

Multiport fuel injector – It just means there’s a separate injector for each cylinder. This is by far the most common set-up, with some advantages in efficiency over the older TBI arrangement.

Direct injection – This uses a single injector for each cylinder, but instead of spraying into the intake system they inject fuel directly into the combustion chamber. This is slightly more efficient, and is becoming more common. Disadvantages are that the intake valves don’t stay as clean without fuel spray, and the injectors themselves are subject to the pressures and conditions of the combustion chamber.

What Does It Cost To Repair a Fuel Injection System?

The average cost to replace a fuel injector on most vehicles, which is one of the more common repair needs, would be about $140, excluding diagnosis.

Diagnosis is usually an hour of labor, though if an injector fails electrically and triggers a code the diagnosis of that is about as simple as they come, and many shops would fold that into the replacement labor.

Because fuel injection is a complex system, the costs associated with a repair can vary fairly widely. Here are a few more specific examples of the fuel injector replacement cost on common vehicles in order to get a better understanding of what is involved in a repair (using an average shop rate of $80 per hour as a baseline).

1. A 2014 Dodge Journey 3.6L has a check engine light and a misfire. The technician gets code P0304 for a cylinder 4 misfire. After diagnosing, they find that the cylinder 4 injector wiring is open.

- Diagnosis – 1.0hr at $80/hr, $80

- Wiring repair – 0.5hrs at $80/hr, $40

- Total cost of repair – $120

2. A 2012 Ford Focus 2.0L has a check engine light and a misfire. The technician pulls codes and diagnoses an open in the cylinder 2 fuel injector.

- Diagnosis – 1.0hr at $80/hr, $80

- Remove and replace direct injector – 1.1hrs at $80/hr, $88

- Fuel injector – approx. $85

- Total cost of repair – $253

3. A 2008 Chevrolet Cobalt 2.2L has an intermittent rough idle with a check engine light. The technician diagnoses injectors sticking and recommends an injector cleaning.

- Diagnosis – 1.0hr at $80/hr, $80

- Injector cleaning – 0.9hrs at $80/hr, $72

- Injector cleaner – approx. $50

- Total cost of repair – $202

4. A 2015 Audi A4 2.0L runs rough and lacks power. The technician diagnoses the high-pressure fuel pump as failed.

- Diagnosis – 1.0hr at $80/hr, $80

- Remove and replace pump – 0.9hrs at $80/hr, $72

- Fuel pump – approx. $310

- Total cost of repair – $452

As we see, the cost to replace fuel injectors can vary fairly widely depending on what type of repair is needed which can be anywhere from $10 to $200 for a simple electrical repair or injection cleaning service, and it can run much higher if more parts and diagnosis are involved.

What Can Go Wrong With Fuel Injection Systems?

Fuel injection systems can fail in two main ways – either a mechanical or electrical failure.

Mechanical failures of the injection system differ depending on the type of system in the vehicle. For multiport injection, it can include leaking or sticking injectors, fuel pressure regulators, injector seal leaks, as well as clogged spray ports. For direct injection, it includes faulty injectors, high-pressure fuel pumps, leaks, or internal engine damage.

Electrical failures affect the solenoid side of the injector, and they can be caused by a failed solenoid winding, bad connection, faulty wiring or a bad ECM. On a modern vehicle this will set a code and turn on the engine light, and then diagnosis follows the specific code. The circuits involved are relatively simple, and diagnostics are straightforward most of the time.

How Can You Avoid Fuel Injection Repairs?

Many manufacturers recommend an intake system cleaning on a 15,000 to 30,000-mile interval. This runs cleaning additives through the intake system and the fuel system, and (at least in theory) keeps the injectors in good shape. The gas additive cleaner is the more important thing for cleaning injectors and maintaining a good spray pattern, and it can be done simply and cheaply with products widely available to consumers.

FAQ

Yes, but it’s a bad idea. A misfire is usually caused, and that either puts the engine into limp mode, or circulates raw fuel into the exhaust where it can damage the catalytic converter.

Yes. Whether the failure is on the electrical side or the fuel side it would cause a misfire which the ECM would detect, setting a code and turning on the check engine light.

There is no predictable service interval or expected lifespan, so injectors are usually only replaced when they have failed.