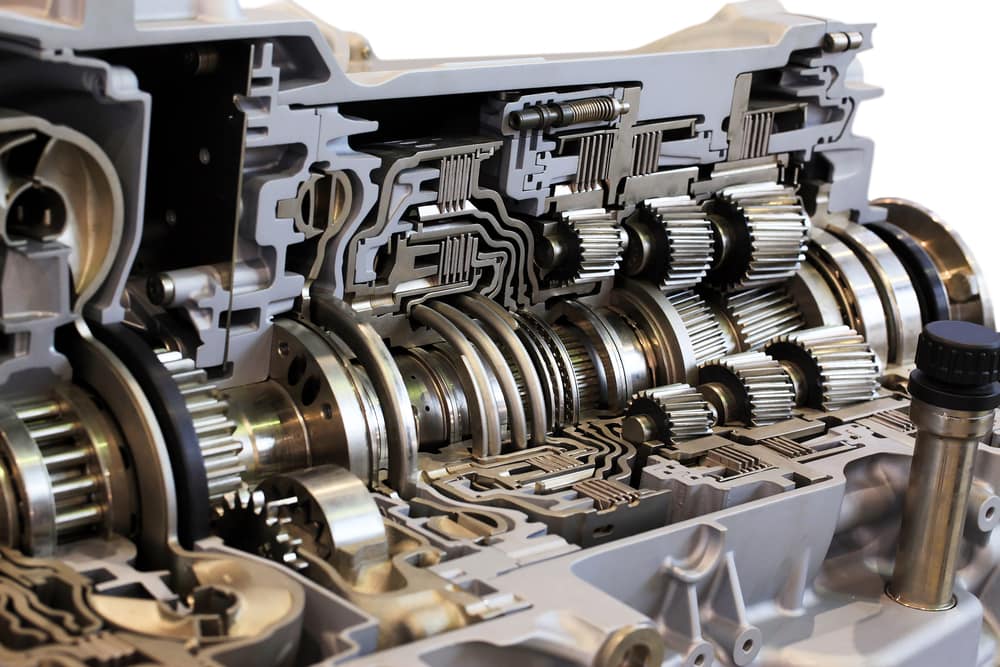

If the engine is the heart of a car, the crankshaft is the heart of the engine. It is the primary moving part to which the pistons and connecting rods attach, which drives the transmission on one end and the camshaft and accessories on the other.

To replace the crankshaft the transmission has to be removed and the engine has to be out of the vehicle on an engine stand. Turned upside-down, the front covers, timing gear, and the oil pan are then removed, at which point the connecting rod and main bearing caps can be pulled. With those undone, the crankshaft can be lifted out of the engine. When replacing a crankshaft the main and rod bearings are usually replaced as well.

Reassembly is particularly time-consuming and delicate, as everything has to be measured to exact tolerances, and everything has to be very clean. The main bearings and connecting rod bearings have specifications for how much play is allowed in them, down to the ten-thousandth of an inch. They can’t be measured directly, but usually, a thin strip of plastic is laid on each bearing surface, which is then torqued down and taken back apart. How much the plastic has crushed can be compared to a scale, which shows how much clearance there is. Bearings can be replaced with slightly under or over-sized ones to gain the correct clearances.

Cost of Crankshaft Replacement

The average cost to replace a crankshaft is $2500. The parts are costly but most of that is labor, and the operation involved a great deal of disassembly and handling of parts. The odds of unexpected problems is pretty high, so most shops will add at least a couple of hundred dollars to the estimate beyond what they know will be needed.

For some more specific examples of the costs to replace the crankshaft on some common vehicles, using $100 an hour as a labor rate:

For a 2009 Ram 1500 with four wheel drive and the 5.7 liter Hemi engine, the labor time to replace the crankshaft is 19.9 hours. A factory crankshaft and bearings costs about $400 (though availability may be limited – the part is currently discontinued), and an Enginetech crankshaft and bearing set costs about $500. Miscellaneous seals and fluids adds about $200. That makes the job about $2500 using factory parts, or about $2600 using aftermarket parts.

For a 2008 Chevrolet Malibu with a 3.6 liter engine the labor time to replace the crankshaft is 17.1 hours. A factory crankshaft and bearing kit costs about $560, and an aftermarket crankshaft is unavailable at the time of this writing. Adding in $200 or so for fluids and seals, this would make the job about $2470, using OE parts.

For a 2006 Honda Accord with the 2.4 liter engine, the labor time to replace the crankshaft is 16.1 hours. A factory crankshaft and bearings comes to about $700, and there is currently no aftermarket crankshaft available. Adding in for fluids and seals, this would make the job about $2510, using OE parts.

Reasons to Replace the Crankshaft

On the front end of the crankshaft a harmonic balancer is held on by a heavy bolt. On occasion when the bolt needs to be removed for other servicing it might break off, or strip the threads. Which shouldn’t be as common as it is, but it’s a stretch-bolt on most engines, meaning it’s tightened to the point that the metal stretches, and it isn’t supposed to be re-used. They’re re-used often enough, and fatigue can cause it the snap, and it’s in a very difficult spot to successfully extract and repair.

On the other end of the crankshaft the flexplate or flywheel is attached, and sometimes there is a pilot bearing pressed in to stabilize the transmission input shaft. The threads for the bolts holding the flexplate or flywheel can be damaged, and sometimes the machined hole for the pilot bearing can get beat up if the bearing fails. All of those are pretty high-stress connections with no room for error, and any problems could call for crankshaft replacement.

The crankshaft also has machined bearing surfaces at each main bearing where it is held to the engine block, and at each bearing surface where the connecting rods attach. There are also two thrust bearing surfaces, where bearings hold the crankshaft in a stable fore and aft position. All these bearing are lubricated by motor oil, and any problem with the oil (if it’s contaminated, old or dirty) can cause wear on the crankshaft. There is a certain allowable limit for wear, and a machine shop can resurface minor issues, but in most cases it’s a better idea to replace a damaged crankshaft.

Reasons to Replace the Whole Engine Instead

If the problem with the crankshaft is worn or spun bearings, that is usually the result of age or poor maintenance, or abuse, such as an over-revved engine. Replacing the crankshaft may solve some problems, but leave other serious problems untouched. The cost of the crankshaft replacement already approaches the cost of replacing the engine (varying around $4300 for a remanufactured engine installed, on average), so if it is likely that there are more issues with the engine it may be cheaper just to replace it.

Warranty is another issue, and one that leans many shops toward whole engine replacement. If a crankshaft is replaced, the only warranty is on the crankshaft itself. Anything else that goes wrong with the engine later is a new problem and a new expense. On an older engine problems can come up with some regularity, and customers are most often unhappy to keep paying for new repairs after such a large expense. If the engine is replaced, however, then the whole engine usually falls under a good warranty, and service is covered for a time. The shop that did the work can have more confidence in a satisfied long-term customer, even if the initial cost is higher. Most often remanufactured engines for passenger vehicles come with a three year warranty.

FAQ

One sign is low oil pressure. This can indicate an isolated oil pump problem, but it can also be caused by excess wear in the crankshaft main bearings.

If the issue is age and wear or neglect, then probably yes. If it’s something else then perhaps not; the job is usually priced out either way and the decision left to the customer.

Yes, usually. Worn bearing surfaces can be machined down and oversized bearings installed. If it’s a problem with the threads or flanges then machines shops are capable of repairing most issues.