The blower motor resistor is in charge of regulating the speed of the blower motor. Usually it is mounted underneath the dash on the passenger side of the vehicle, bolted into the ductwork upstream of the blower motor. The easiest way to locate it is to find the blower motor; the other end of the wiring that plugs into the blower motor comes directly from the blower motor resistor.

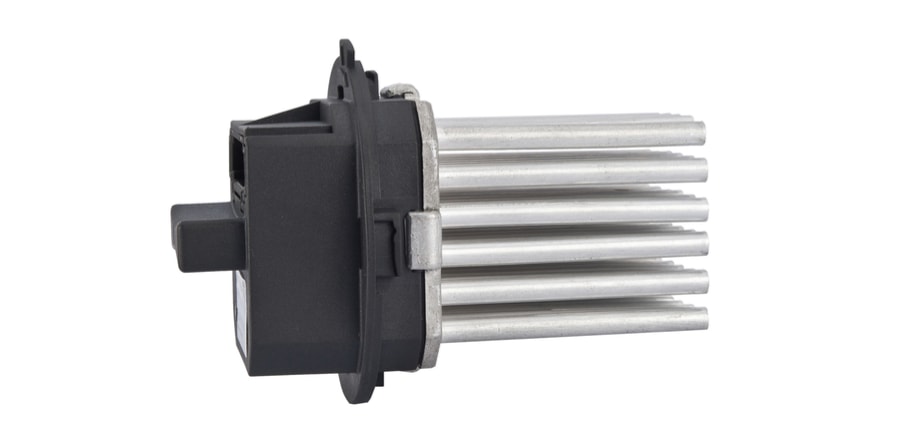

The classic blower motor resistor is a block with various resistance wires inside it through which the current for the blower motor flows, depending on the position of the blower switch. When the current has to go through a higher resistance wire, it will reduce the voltage going to the blower motor, slowing the blower fan down.

A newer style of blower resistor uses electronics to send small pulses of current to the blower motor, and the frequency and duration of the pulses determine the speed of the blower fan.

Cost To Replace a Blower Motor Resistor

Blower motor resistors can be fairly cheap if they are a manual resistor block style. However, the newer computer-controlled resistors can be expensive since they contain sensitive electronics.

Blower motor resistors are a common failure point in the HVAC system and are usually easy to access and replace; most of the time, the job can be completed in about an hour.

Here are a few examples of how much it might cost to replace a blower motor resistor in some common vehicles, using a typical shop rate of $150/hr:

For a 2011 Toyota Corolla with a 1.8 liter engine and manual HVAC controls, the labor time to replace the blower resistor is .7 of an hour. A Beck/Arnley part costs about $35, or an OE replacement list for $39. That would make the job about $140 using aftermarket parts or about $144 using factory parts.

For a 2015 F-150 5.0L with automatic temperature control, the labor time to replace the blower resistor is .7 of an hour. A UAC replacement costs about $35, or an OE replacement lists for $48. That would make the job about $130 using aftermarket parts, or about $143 using OE parts.

For a 2016 Audi RS4 3.0L with automatic temperature control, the labor time to replace the blower speed control module is .9 of an hour. A Standard replacement part costs about $330, or an OE replacement module lists for $610. This makes the job about $465 using aftermarket parts, or about $745 using factory parts.

For a 2014 Jeep Wrangler 3.6L with automatic temperature control, the labor time to replace the blower motor resistor is .8 of an hour. A Four Seasons replacement part costs about $170, or an OE part lists for $180. That makes the job about $290 using aftermarket parts, or about $300 using factory parts.

In all of the above cases, a half hour to an hour of diagnosis might be added.

What are the Symptoms of a Failed Blower Motor?

usually due to heat damage on the resistor wires, while the high speed setting uses a conventional wire rather than a resistor wire. The reason the resistor is typically bolted into an air duct is to help manage the heat the unit develops in normal operation, but heat damage is still possible.

On a newer vehicle with automatic HVAC, the blower motor resistor is electronic, and if the resistor block fails, the blower will most likely not work at any speed.

What Else Might be Needed?

The most common cause of blower resistor failure is heat damage, and what damages the resistor can also damage the wiring. It is common to have to replace the wiring connector at the blower resistor; usually these are commonly available and can be spliced in relatively easily. In most cases, it would add about $150 to the total bill. If the blower operates intermittently, that usually indicates damage to the connector.

Generally, a failed blower resistor won’t cause other issues beyond possibly damaging the wiring attached to it, but there is a long list of other potential causes of a blower motor not working. There will be a fuse or a fusible link, and there may be a relay. Before condemning a blower resistor, good practice is to make sure that it has power available to it.

The blower motor itself should be checked to make sure it will run if it receives power; sometimes they are removed and bench-checked if the connections under the dash are awkward to get to. In most cases, they’re easy to test and easy to replace if necessary.

There are also the dash controls themselves, which sometimes develop issues. A simple mechanical blower switch is easy to test, but the trend for some time has been toward electronic controls, which can be very difficult to diagnose without a good scanner.

While working in that area, most shops would inspect the cabin filter. If that needs replacing, it should be replaced. If the blower has to work harder to drive air through a restricted filter, that can cause stress on the motor and resistor, and contribute to heat damage.

FAQ’s

- How long should a blower resistor last?

It should last years, but that can depend on how it is used. On an old-style system, running the blower on high is easier on the component than running it at reduced speeds. Making sure the blower motor fan spins freely can also help, though any problem there should show up as an obvious noise. Checking and replacing the cabin filter as needed also helps.

- Can I replace my own blower resistor?

Probably. Access is usually gained by removing the glove-box door or an under-dash panel. From there, the resistor is usually held by a couple small screws. No special tools would be needed, unless there is heat damage to the wiring, in which case a wire stripper and crimper would make that part fairly easy.

- Can I drive with a failed blower resistor?

In most cases, yes. But in the winter, you’ll have no defrost, and in the summer, no AC. Both of those situations can be bad, depending on the weather.