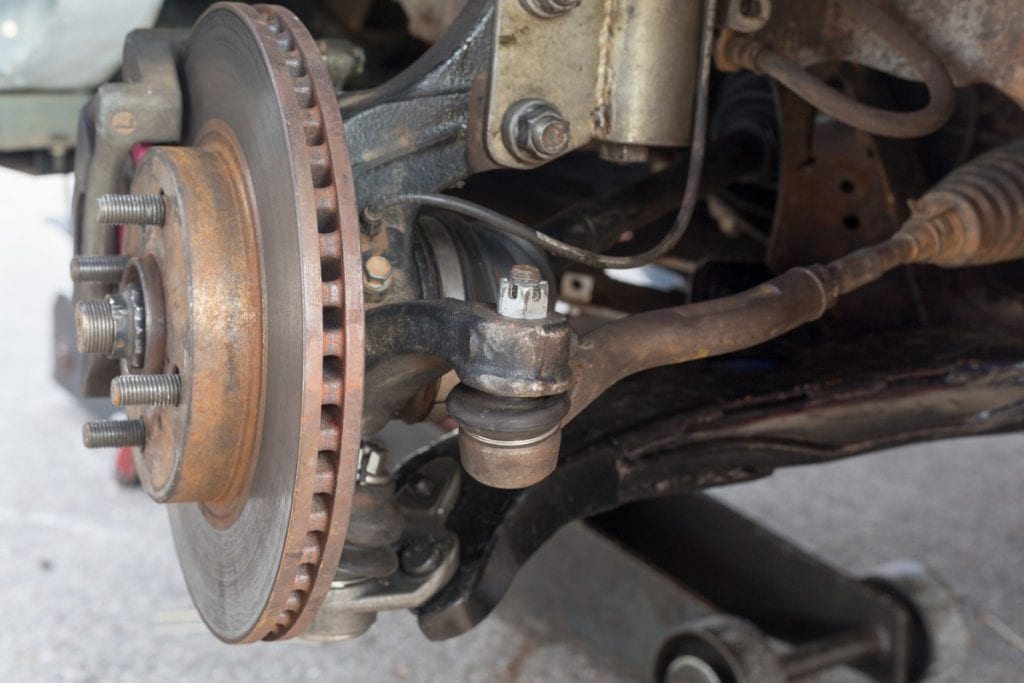

On the front suspension of a vehicle, when you steer, the front knuckles pivot between two points at each wheel. For an independent front suspension vehicle, those two pivot points are the upper and lower ball joints. Solid axle four wheel drive vehicles also use upper and lower ball joints on each front corner as pivot points for steering. On a Macpherson strut suspension, the two points are an upper strut bearing and a lower ball joint. On some newer design multi-link independent suspensions, there are two upper and two lower ball joints per corner, which are generally serviced by replacing individual control arms as needed.

A ball joint is just what it sounds like – a stud with a ball-end that’s trapped in a housing socket, so it can rotate, pivot, and move relatively freely. On the stud side, there’s a tapered pin with a threaded end, so it locks into a machined tapered hole, where it is secured by a nut. A ball joint can be pressed or bolted to a control arm with its stud locked down in the knuckle. Or it can be the reverse – pressed into the knuckle, then it’s stud locking into a control arm. Many ball joints are non-serviceable because they have no grease fittings. Others have fittings that are traditionally greased during an oil change service. Most of the time nowadays, it’s necessary to ask to have the chassis lube-points greased during an oil change, if it can be done.

Replacing ball joints isn’t usually too difficult, given a few special tools. To break the tapered stud loose, there’s a tool called a “pickle fork”. Then, if the ball joint is a press-fit a special ball joint press is used, with various adapters to fit various models. After ball joint replacement, the alignment does need to be re-done. In many cases now, it’s necessary, or at least most economical, to replace the ball joint with the whole control arm. Ball joints may last the life of a vehicle, but they are a high-stress part, and a lot depends on driving conditions. Most vehicles have an inspection schedule, including the ball joints, in their owner’s manual.

Related Article: Suspension Repair Cost Guide

Signs of a Failing Ball Joint

In the majority of cases, there are no signs. Noise going over bumps can be one, but that symptom is usually caused by other things. A knocking noise when applying the brakes is possible, as the stopping forces have to pass through the ball joint or joints into the rest of the vehicle. But knocking noises when braking are usually caused by other things as well. In both cases, the issue is that the weight of the vehicle is leveraged against the ball joints, so even if one is loose, it will still sit in a fixed position, and the various forces of driving are usually not enough to cause movement.

Sometimes ball joints are suggested as the cause of a vibration in a vehicle at speed. For the reasons given above, that’s also caused by other things, and can’t be caused by a ball joint.

If a ball joint has radial play, it will usually cause a negative camber issue; the wheel on the affected corner will lean in at the top. Any change like that impacts the toe angle, which causes tire wear. So if a vehicle is getting regular tire rotations, the shop will usually look at tire wear at that time and recommend an alignment if there is any unusual wear. Every alignment starts with a check of the suspension, and that’s where a ball joint problem would typically be noticed.

Costs of Ball Joint Replacement

On average, it costs about $300 to replace a ball joint on a passenger vehicle. It costs about $500 on average to replace a pair of upper and lower ball joints (one side) on a four wheel drive vehicle.

For some more specific estimates of the cost to replace ball joints on common vehicles, using $150 an hour as a labor rate, and adding in an average amount for a wheel alignment:

For a 2007 Subaru Forester, the labor to replace the front lower ball joint is .8 of an hour. Like most Subarus, it’s pinned at the control arm and held at the knuckle with a pinch bolt, so it separates out pretty easily. A factory part costs about $49, or a Moog part costs about $38. This makes the cost of replacing both lower ball joints about $338 using factory parts, or about $316 using aftermarket parts.

For a 2003 Honda Civic, the labor time to replace the front lower ball joint is 2 hours. It’s pressed into the knuckle, which is usually removed for the service. A factory part costs about $65, or a Mevotech part costs about $55. This makes the cost of replacing one lower ball joint about $365 using factory parts, or about $355 using aftermarket parts.

For a 2000 Jeep Grand Cherokee four wheel drive, which uses a solid front axle, the labor time to replace the upper and lower ball joints on one front corner is 1.9 hours. A factory pair costs about $216, and a pair of Dorman greaseable ball joints costs about $96. This makes the cost of replacing an upper and lower ball joint on one corner about $500 using OE parts, or about $381 using aftermarket parts.

For a 1997 Chevrolet K1500 four wheel drive with torsion bar suspension, the labor time to replace the front ball joints on one corner is 4 hours. This has an independent suspension, but has the disadvantage of the original ball joints being held in by heavy rivets, which must be cut and driven out. Replacement ball joints are then held in place with bolts. A factory upper and lower ball joint set costs about $218, or a Mevotech heavy duty set costs about $90. This makes the job about $818 using OE parts, or about $690 using aftermarket parts. There are also a variety of different suspensions and sub-model options for that truck, so often visual inspection and measurement are needed to get the correct parts and labor times.

After ball joint replacement, a wheel alignment does need to be done.

Related article: Wheel Alignment Cost Guide

Inspecting Ball Joints, and What Can Go Wrong

Ball joints are typically inspected only for play. In most cases, there should be no side play and no up and down play; technically, that’s radial and axial play, respectively. In principle, the ball joints should be inspected, the amount of play measured, and then that compared to the amount of allowable play. Usually, play is measured in thousandths of an inch, using a dial indicator and a fixture. Ball joints are considered safety items, so all the specs and methods are published and commonly available information to mechanics.

But in practice, in most cases, a good ball joint is “tight”, and a ball joint with any amount of play is recommended for replacement. This can lead to some mistakes in diagnosis. Sometimes there is an allowable amount of play, radial or axial, and sometimes axial play is designed into a ball joint depending on the engineering of the suspension. It is always fair to ask the questions, “how much play is allowed?” and “how much play does it have?” A mechanic who did an inspection correctly generally appreciates being able to inform a customer. One who didn’t do an inspection correctly would have to look things up, and then might learn something.

In some cases, ball joints are also sold for “leaking”, which is not an actual cause for replacement. Whether a ball joint has grease fittings or not, it will use a flexible boot to protect the socket from the elements. Frequently, these will leak, but that isn’t necessarily a problem. Older ball joint designs were supposed to leak, and the general rule was that you knew there was enough grease inside if you could see some grease outside. A newer non-greasable ball joint will likely have a shorter lifespan if the boot protecting the socket is torn, but there’s still no great reason to replace a ball joint that hasn’t failed yet. Unless, perhaps, it has to be removed for another service.

When using the cheapest parts available, one problem that comes up sometimes is that the tapers aren’t ground correctly. When the bolt or castle nut is tightened down to lock the taper, the stud can be pulled too far up through the machined opening to install a cotter pin effectively. It can also draw up to the point that the ball binds in the socket. In either case, the best solution is to utilize the parts warranty and try another ball joint; a safety item that doesn’t fit right shouldn’t be installed.

FAQ

Generally not. The ball joints are an important part of the vehicle’s steering and suspension, and if a ball joint is worn past its allowed limits, that means it is unsafe by definition. Ball joint failure can mean the suspension coming apart and a loss of vehicle control.

Yes, it is likely that an alignment is needed, and having the alignment checked afterwards is much better than waiting to see if the tires wear out.

If a vehicle is in for a wheel alignment, the ball joints are usually inspected. Also, if a safety inspection is required or requested, the ball joints should be checked. In most cases, they are pretty durable and reliable; this is not a common problem except at high mileage.

If they have zerk fittings, then they should be greased at every oil change. Most newer vehicles don’t have grease fittings, but you don’t know for sure without looking. It’s usually a good idea to ask that it be done or checked when having oil changed.

That’s always a judgment call. You don’t need to replace any ball joints unless they fail inspection. But when one ball joint fails due to age and wear, the other ones might not be far behind, even if they pass inspection. It can come down to the cost and difficulty of the job, which vary between different vehicle designs.