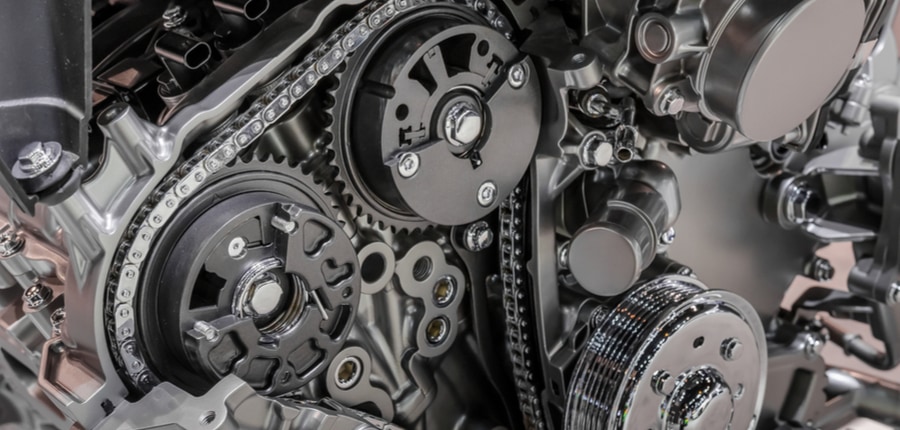

Some engines rely on a single chain to operate overhead cams, some rely on two or three chains, and some have more than that. In any case, all are directly timed to the crankshaft. There is a fixed order to disassembly and reassembly, and there are marks to get everything set up correctly.

In order to access the timing chain, it’s usually necessary to remove all the accessories from the front of the engine, then, remove the timing cover. Given the typically large cost of labor, the chain replacement will be done with the chain tensioner and guides as well. This is usually done in most cases so that there should be no reason to do the job again any time soon.

Timing Chain Replacement Costs

The cost of timing chain replacements varies depending on the type of vehicle and model, the type of parts used, and the labor rate imposed by different auto service shops across the country. To illustrate these factors, the following common vehicle models as used as examples using $100 per hour as a labor rate:

- For a 2009 Dodge Charger with a 5.7-liter engine, the estimated labor time is around 7.3 hours. A factory chain, guide, and tensioner set cost about $95, and a Melling timing chain price per set is about $79. The total cost to complete the job would be about $825 using OE parts, or about $809 using aftermarket parts.

- For a 2013 Chevrolet 1500 4wd pickup with a 5.3-liter engine, the estimated labor time is around 9 hours. A factory timing chain and tensioner cost about $99, and a Cloyes timing chain set costs about $59. The total cost to complete the job would be about $999 using OE parts, or about $959 using aftermarket parts.

- For a 2009 Nissan Altima with a 2.5-liter engine, the estimated labor time is around 6.8 hours. A Melling timing chain set with chains, tensioners and guides, and sprockets cost about $175. The total cost to complete the job would be about $855.

- For a 2007 Honda Fit with a 1.5-liter engine, the estimated labor time is around 5.9 hours. A factory timing chain, tensioner and guides cost about $269, and a Cloyes timing chain set costs about $141. The total timing chain replacement cost would be about $859 using OE parts, or about $710 using aftermarket parts.

In all of the above cases, there would be additional costs for fluids, seals, and gasket materials necessary to reseal the timing cover and finish the job. In most cases of internal engine work, an oil change after completion is usually recommended as well which would also be an additional cost.

In many cases, it’s necessary to evacuate the AC system in order to remove the compressor or hoses for access to the timing chain. That’s not usually included in the labor time and maybe an additional cost in parts and labor.

More About Timing Chains

One of the main things that must be engineered for in an internal combustion engine is the opening and closing of the intake and exhaust valves as the engine turns. The crankshaft operates the pistons and the camshaft operates the valves.

The valves have to be timed precisely to the movement of the pistons. However, one thing that complicates this is the requirement that the valves operate at exactly half the speed of the rotation of the crankshaft.

This requires a geared link where one shaft drives another at half-speed. There are different ways of accomplishing this.

Some engines have a direct gear drive, and some engines have a belt-drive. Both have disadvantages as far as wear and maintenance, or noise is concerned.

A drive using a timing chain is the most common compromise, giving relatively quiet operation, very low maintenance, and precise operation.

Some timing chain designs are simply two sprockets linking the crankshaft to a central camshaft that operates the linkages that operate the valves.

On some older design engines, there was no mechanism to compensate for wear. However, newer designs almost always utilize timing chain tensioner and guides to give more precision to the timing.

A newer design than that is the overhead or the multiple camshafts so that valves can be operated on directly by the cam lobes instead of relying on a chain of linked parts (lifters, pushrods, rocker arms). This has advantages in engine performance and makes it easier to design an engine with more than two valves per cylinder. Nevertheless, it does complicate the timing chain design.

Signs of Timing Chain Wear

In some cases, the noise from the timing chain can be an indication of wear or problems with the timing chain tensioner or guides. It’s usually fairly difficult to tell where internal engine noise is coming from.

A normal method that can isolate a timing chain noise is to remove the serpentine belt and run the engine briefly. Then, with all the various accessories inactive, it should be possible to localize the source of an internal engine noise using a mechanic’s stethoscope to listen at the timing cover, engine block, valve covers, etc. If it’s a timing chain issue, it’s usually pretty distinctive.

A timing chain will effectively lengthen as it wears. On most modern engines there are sensors on the crankshaft and the camshaft that read their exact positions and monitor their relative positions.

As a timing chain wears and lengthens, the cam position will drift relative to the crank, and then, a cam/crank correlation fault code will be triggered. This will turn on the engine warning light.

Other things can cause the code to be set, and there is a diagnostic procedure to determine whether it’s a timing chain problem or something else.

Other Related Repairs

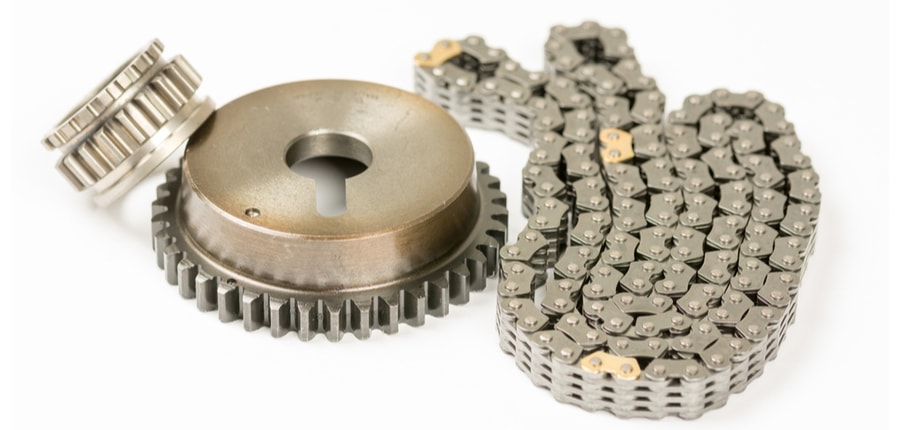

Given the amount of disassembly involved to replace a timing chain, there are a number of related items that may be found in need of replacement. The most common ones are the sprockets that the chain rides on.

If a chain is stretched and worn, it can cause a wear pattern on the sprockets that a new chain won’t mate up with well. The sprocket that sees the most wear is the crank sprocket as this has half the teeth of the cam or intermediate sprockets and is the primary driver of the timing chain. Cam sprockets are sometimes replaced for wear, but much less often.

The water pump is another common item. This only needs to be replaced if the bearings are worn or rough, or if it shows signs of internal leakage. Even so, water pumps do wear out over time.

The removal of the timing cover to access the chains involves draining the cooling system and removing the water pump in most cases. For that reason, replacing an older water pump while it is already removed is an economical measure of preventative maintenance.