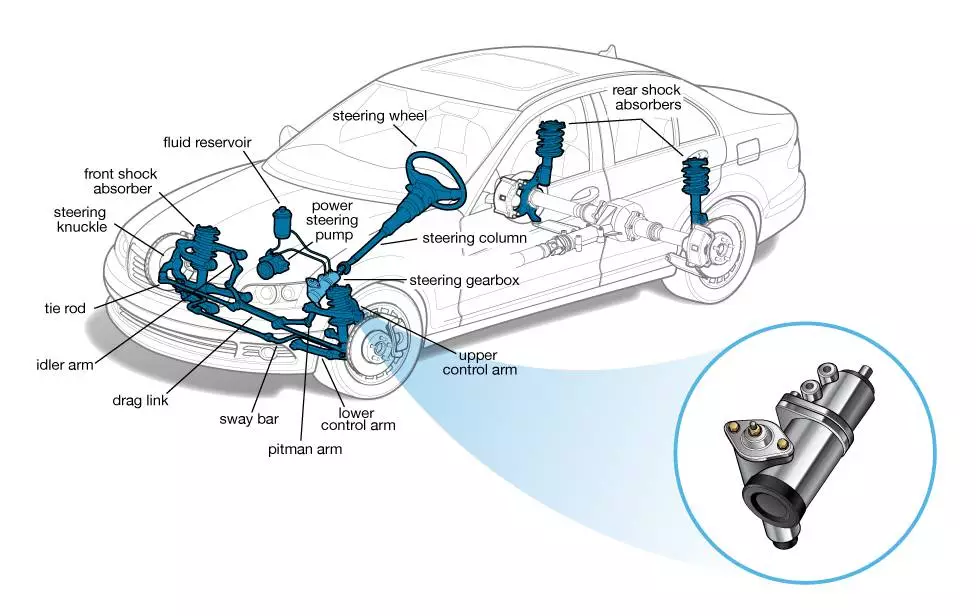

A steering gearbox is an important part of the chain of mechanisms that turn the front wheels of a vehicle when the driver turns the steering wheel. Most modern passenger cars use an alternative method for this, which is a steering rack and pinion, but many light trucks and most heavy trucks still use a steering gearbox, which is an older design. In general, a rack and pinion makes steering easier and more precise, while a steering gearbox is stronger and lasts longer.

Almost all cars now have power steering, so any car with a steering gearbox uses pressurized fluid to assist steering efforts. One power steering fluid line brings fluid in, and the other one takes fluid out. The steering gearbox will also have an input shaft coming in from the steering column and an output shaft connecting to the rest of the steering linkage. Internally, these two shafts are geared together and held in place by bearings and bushings. There are several things that can go wrong, and normal wear and tear almost inevitably leads to issues at some point.

Replacing the steering gearbox means unhooking the clamp from the steering column, removing the pitman arm with a puller, removing the power steering fluid hoses, and unbolting the box from the frame. Afterwards, the vehicle is usually aligned, though the main reason for that is to re-center the steering wheel, as that should be the only thing that changes with replacement, unless other parts are replaced as well.

Costs of Steering Gearbox Replacement

For some rough estimates of steering gearbox replacement costs, assuming a shop rate of $150 an hour:

On a 2017 Jeep Wrangler, the labor time for replacing the steering gearbox is 1.3 hours. A Mopar steering gearbox lists for about $1160, and a rebuilt steering gearbox costs about $400 from various sources. That would make the job about $1360 using OE parts, or $600 using aftermarket parts. Plus alignment, if necessary.

On a 1995 Nissan Pathfinder, the labor time for replacing the steering gearbox is 1.8 hours. An OE steering gearbox lists for about $1430, and a rebuilt unit costs about $400. That would make the job about $1700 using OE parts, or about $670 using aftermarket parts, plus alignment.

On a 2001 Ford F350 with a 7.3 liter engine, the labor time for replacing the steering gearbox is 2.7 hours. It’s a little more difficult to access than average. An OE steering gearbox lists for about $450, and an aftermarket box replacement costs about $370. That would make the job about $855 using OEM parts or about $775 using aftermarket parts.

Causes for a Steering Gearbox Replacement

Fluid leaks are one common problem. As the moving parts wear, the input and output shafts can become loose, which can allow fluid to bypass the seals. Worn-out/dirty power steering fluid or dirty operating conditions can cause wear on the seals, which can also lead to leaks. Sometimes you can replace just one seal, but most of the time, a leaking steering gearbox is thought to be caused by general wear, so the whole thing is just replaced. As with many things these days, labor is so much more costly than the parts that it’s not often worth the risk of having to do the job twice.

Steering system problems can also occur because of internal gearbox wear. The tightness of the bearings is set when the gearbox is put together, and that determines how the gears mesh. As things wear with age and use, the meshing of the gears can loosen up, resulting in “slop” in the steering. Typically, this is noticed as having to move the steering wheel farther than normal to actually steer the vehicle.

What Else Can Seem Like a Bad Steering Gearbox:

Several other things can also cause slop or excess play in the steering, such as worn out or loose tie rod ends. Most of the time, it’s best to have a shop check the whole front suspension of a vehicle when this is the case, and most shops will generally do this for free as a part of a general safety inspection. It’s also common for steering gearbox problems to not be diagnosed with certainty until after other more obvious problems are taken care of.

Some vehicles use a “rag joint” in the steering column in the engine compartment. A worn-out rag joint can seem about the same as a worn out steering gearbox. On the output side of the steering gearbox, it connects to the rest of the steering linkage through a pitman arm and drag link, or center link, and then inner and outer tie rods. All of these can wear out and are fairly easy to check. Any play in a joint can cause too much slop in the steering. Less common is ball joint wear or worn out control arm bushings, but these should also be checked.

Most steering gearboxes have an adjustment at the lock-nut on the top end of the output shaft (called a “sector shaft”) coming out of the box that allows the bearing preload to be set and can compensate for some wear. For the most part, though, the adjustment is made at the factory and isn’t touched after that. Rebuilt boxes often have the adjuster paint-marked, and moving it voids the warranty. For someone experienced, it is a routine and predictable adjustment to make, but it’s also fairly easy to make things worse rather than better by trying to adjust the bearing preloads. So it is one of those things – if a mechanic isn’t certain of how to do it, it’s best not to mess with it.

Frequently Asked Questions

Can I drive with a steering gearbox problem?

If the problem is a leak, it depends on how bad the leak is, and whether it’s practical to keep the fluid topped up. Loosing too much power steering fluid means losing steering assist, which is obviously a bad thing. If the problem is wear, that affects the ability to accurately steering the vehicle. Whether the vehicle can be safely driven then depends on how bad the wear is.

Almost all steering gearboxes are lubricated internally by power steering fluid. The primary maintenance is replacing the fluid, which should be done according to the maintenance schedule in the vehicle’s owners manual. A typical interval is every 30,000 miles.

Due to the design of the power steering system it’s not generally practical to completely drain the system and refill it, so often the reservoir is just suctioned out and filled back up with new fluid. Another common way is to use a simple fluid exchange machine, which is a little better than just changing the reservoir fluid. In either case, any maintenance is better than none.

One of the main ways to reduce the cost of steering gearbox replacement, of course, is to make sure the diagnosis is accurate and that other possibilities have been ruled out, and perhaps having a sector shaft adjustment attempted. After that, one reasonable option is to replace the power steering gearbox with a remanufactured unit rather than a new one. The warranties are often the same either way, and the remanufacturing process is simple enough that it’s usually not a bad way to go.