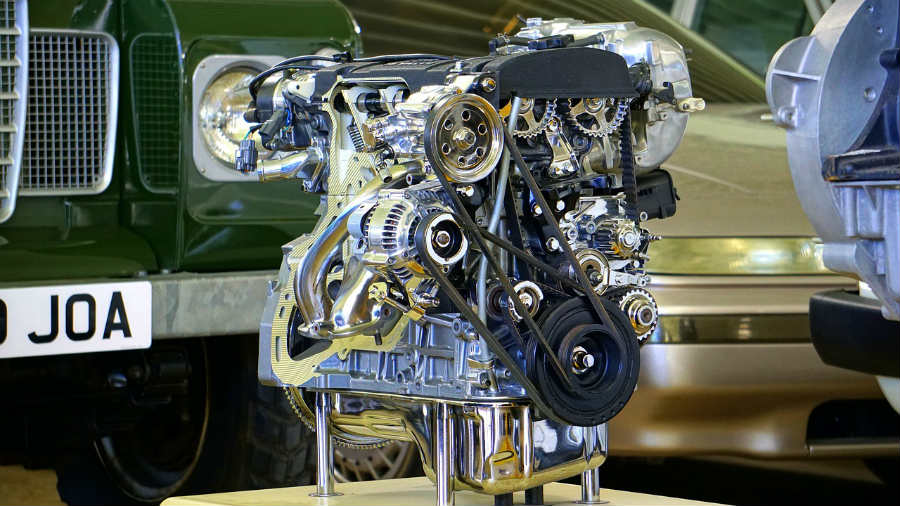

The function of a serpentine belt is very simple: it transmits engine power from the crankshaft to the driven accessories. Typically, those would be the water pump, the alternator, the AC compressor, and the power steering pump. Some engines have fewer things, while others (such as some diesel engines) have more.

A belt tensioner keeps the serpentine belt in constant tension, allowing it to maintain its grip on the accessory pulleys. The operation of replacing a serpentine belt is essentially pivoting the tensioner pulley away and slipping the old belt off, then positioning a new belt into place and releasing the tensioner.

In most cases, it’s an easy operation. Labor is commonly about a half-hour, give or take, on most passenger vehicles and gas-engine trucks. Some diesel engines with a multitude of accessories and difficult access can take as much as 2.1 hours. On vehicles with two or more belts, they will usually be replaced together.

Cost of Serpentine Belt Replacement

Below are some of the serpentine belt replacement cost examples for some vehicle models using the average shop labor rate of $150 an hour:

- 2010 Chevrolet Malibu with the 2.4-liter engine – labor is 0.7 hours, an ACDelco belt costs about $15 or $30. The total job cost would be about $125 at an independent shop or about $135 at a dealership.

- 2007 Volkswagen Jetta with a 2.5-liter engine – labor is one hour, and there are two belts. A pair of Gates replacement belts costs about $45, or an OE set costs about $98. The total job cost would be about $195 at an independent shop or about $248 with dealer parts.

- 2012 Ram 1500 with the 5.7-liter engine – labor is 0.4 hours, a Dayco belt is about $40 while the factory belt runs at around $55. The total job cost would be about $100 with the aftermarket part or $115 with the OE part.

- 2008 Ford F-250 with the 6.4-liter diesel engine – labor (by book time) is 2.1 hours. With the dual alternator option, an OE belt costs about $84, or a Continental belt costs about $34. The cost would be about $400 using OE parts, or about $350 with aftermarket parts.

Of course, the parts and labor costs to replace the serpentine belt vary everywhere—from region to region and shop to shop.

Signs of a Broken Serpentine Belt

The accessories involved vary with different vehicles, but the serpentine belt can run the alternator, the water pump, the power steering pump, and the AC compressor. If an engine is overheating or the steering becomes difficult, looking under the hood to make sure the serpentine belt is in place is a good first check. If the battery light comes on, step one of the diagnosis is also to make sure the serpentine belt is still there.

How Serpentine Belts Fail

Serpentine belts are made from high-quality rubber with a strong woven backing. The rubber has a very good grip and resilience when it’s fresh, but it hardens and loses those properties as it ages.

Its useful life varies, but inspection and possible replacement at 5 years or 90,000 miles is a common recommendation. On a serpentine belt, the common sign of age-related failure is slipping on the pulleys, which can cause a squealing noise, most often when a vehicle is first started. One trick to verify that it’s just belt noise is to spray a little water on the belt and see if the noise goes away.

In other cases, the belt doesn’t slip or make noise, but the rubber can start to crack across the ribbed section. It’s a good idea to replace it then.

Belts can also come apart, the fabric backing can tear and shred into the pulleys as the engine spins. Usually, that only happens after the belt has begun to crack. Hence, it’s a good idea to replace a cracked belt.

Oil contamination from leaks can also cause a belt to fail, sometimes causing the rubber to become sticky and making a mess of the pulleys. Sometimes in that case, cleaning the old pulleys can add labor to the job if necessary, and any oil leaks that caused the issue should be corrected at the same time.

What Else Can Go Wrong?

The belt tensioner is usually checked when the belt is off. These have an internal spring (or sometimes an oil-charged mechanism) that holds the belt in tension and should be checked for smoothness of motion and even tension. As the tensioner works, it must move with any irregularities in the other pulleys, and this constant motion can cause wear in the tensioner housing. This can be checked for play or damage with the belt off.

Related Article: Belt Tensioner Replacement Cost

While the belt is off, it’s a good idea to spin the pulleys of the accessories (and any idler pulleys) to verify that the bearings are smooth. Sometimes a failed belt is caused by a failing bearing, and sometimes what is taken for belt noise turns out to be noise in something driven by the belt. It’s not always possible to verify a problem prior to removing the belt.

Another thing that can go wrong is pulley alignment. If the pulleys aren’t aligned on the same plane, the belt can jump a rib, wear on its edges, or make noise. Bearing issues can cause pulley misalignment or wear in the body of a belt tensioner. On the harmonic balancer, sometimes the bonding of the outer pulley to the inner machined core can fail, and that also causes a misalignment.

Pulleys can also become contaminated. If there is a leak that has gotten onto the belt, it can leave gummy deposits or even fragments of the old, worn belt lodged in the pulley grooves.

It’s always a good idea to check these and clean as necessary to avoid further problems. And, of course, address leaks to prevent a recurrence.

Stretch Belts

This is a type of serpentine belt that is becoming more common; mostly as a non-primary belt on several makes of vehicles. Unlike the conventional serpentine belt, it has a synthetic rubber compound over an elastic core.

The easiest way to identify a stretch belt is that it uses no belt tensioner but instead uses its own elastic properties to maintain tension.

Stretch belts usually don’t crack or wear as obviously as a conventional serpentine belt. Sometimes, they have a specification for rib depth, which can be measured with special tools, and the casing can be examined for integrity.

A stretch belt requires a special tool to install and is usually considered “single-use” due to the ease with which it can be damaged. If a stretch belt has to be removed, it is usually recommended that it be replaced.

The lifespan of a stretch belt is estimated to be about the same as that of a conventional serpentine belt. Hence, the usual recommendation is to replace both of them at the same time when servicing a primary serpentine belt on an engine that also has a secondary stretch belt.

Frequently Asked Questions

It depends on the accessories it runs. If just an AC belt is missing, that’s ok. If a water pump belt is missing, the engine would begin to overheat fairly rapidly. If a power steering pump belt is missing, you lose the ability to steer well. If an alternator belt is missing, the battery can run the vehicle for maybe an hour, after which it will begin to shut down.

On most vehicles, it’s not too hard, and online guides are available to guide the work.